Laser Blanking Line

Item No. - CKL 001

It is suitable for various metal ware production like cookware, kitchenware, tableware that made of stainless steel, composite steel, copper, aluminum, iron etc.

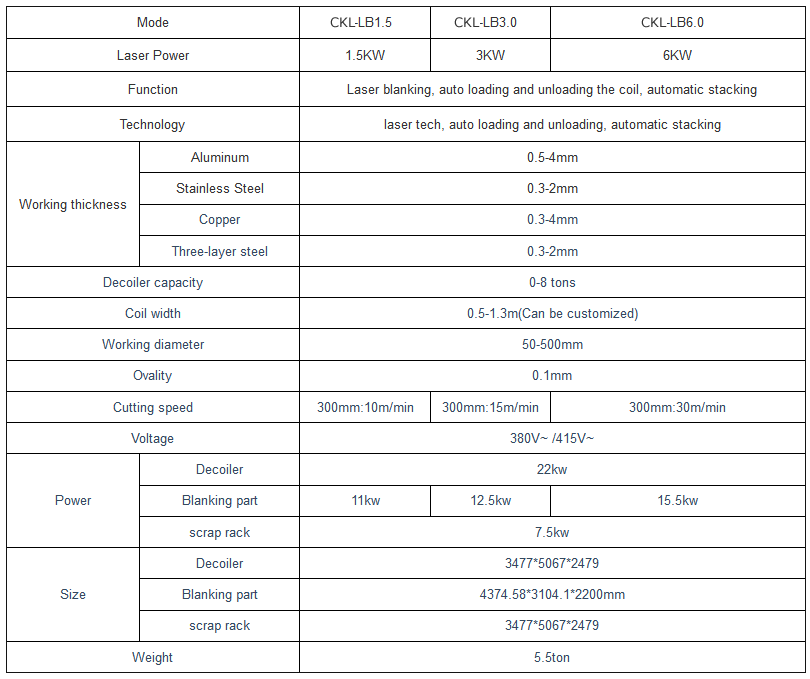

Specifications

Advantage

- Wide Applications: Suitable for various metal ware production like

cookware, kitchenware, tableware that made of stainless steel, composite

steel, copper,aluminum, iron etc.

- Save Cost: Laser cutting line can replace traditional blanking line

punch machine so that no mould installation.

- Easier Operation: Any shape can be cut out.Cutting range from

60-1000mm in diameter. The cutting edging is smooth and no burr.

- Machine Construction: Uncoiling+Deflflection Regulation+Laser

Cutting+Cut Sheet Collecting +Auto Stacking +Scrap Reeling.

- Auto Loading & Uncoiling brings the advantage of labor-saving &High

degree of automation.

- Any Shape can be cut out. Cutting range from 60-1000mm in diameter.

The cutting edging is smooth and no burr.

- Automatic Collection & Stacking cut sheets are automatically

collected and stacked to realize labour-saving.

- Automatic Scrape Recovery scrap rewinding, easy and simple unloading