Double Stations Servo Straight Circular Laser Welding Machine

Item No. - VFL 060

The machine is mainly used for the laser welding process of the inner tank and the outer shell of the cup and pot after press-fitting.

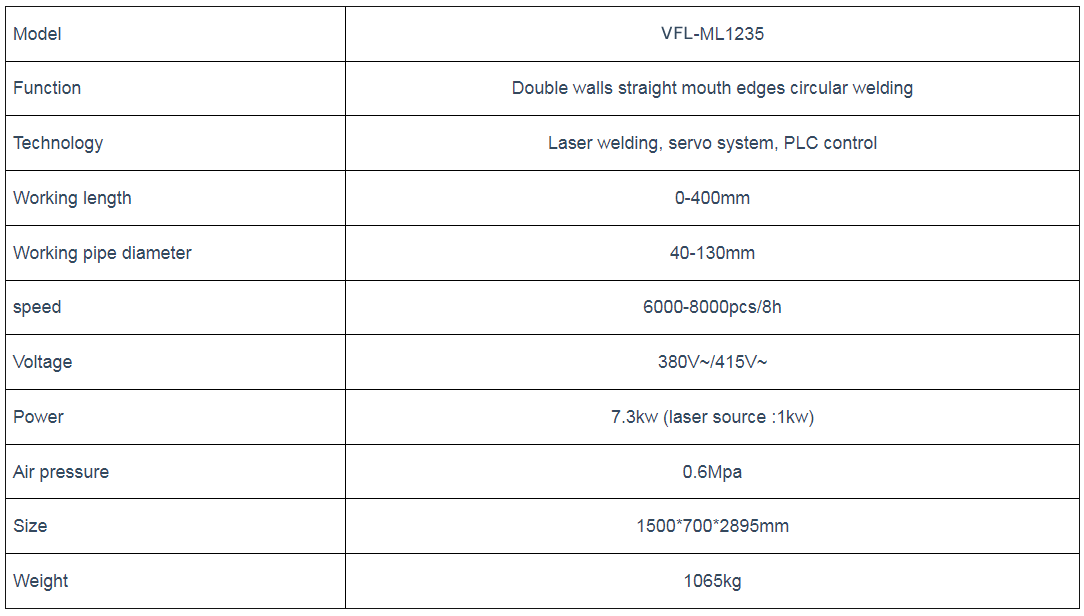

Specifications

Advantage

- Bottle pressing and welding 2 process fnished in 1 machine.

- High production capacitv:2pcs fnished in 1 machine at same time.

- Easy operation and setting.

- Less effort and high gain capacity.

- Manpower saving.

- No argon gas requirement. No need any argon torch setting.

Application

- The machine is mainly used for the laser welding process of the inner

tank and the outer shell of the cup and pot after press-fitting.

- The frame

part is welded with sheet metal and 5# square tube.

- The position

and angle of the welding gun are easy to adjust. The goggles

automatically protect the face.

- The welding

torch structure and cup mouth have good flexibility, easy operation,

high efficiency and good stability.

- Put the

product into the equipment mold, press to start, the upper cylinder head

mold is matched, the pneumatic chuck clamps the product spindle to

rotate, the handwheel fine-tunes the position of the welding torch, and

the ignition welding is completed for one week.

- Processed

products are stable. It is an ideal equipment for metal utensil

manufacturing and processing enterprises.