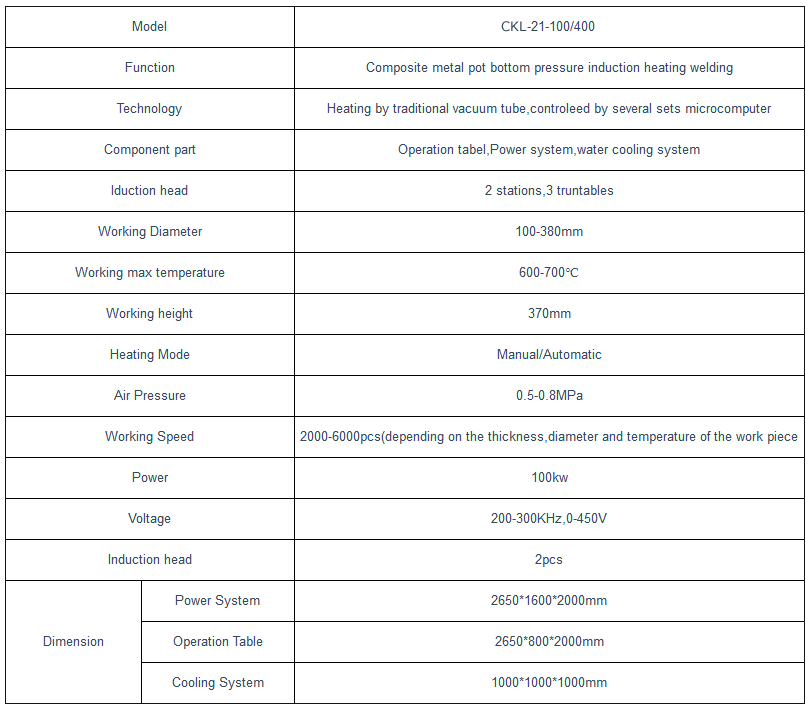

Multi Layer Composite Bottom Brazing Machine

Item No. - CKL 018

Bottom brazing machine is used for cookware composite bottom welding of stainless steel/cooper/aluminium pan, pot, and can also be used for plane heating of other work piece.

Specifications

Advantage

- The higher the frequency, the higher the technical requirements, and

the more uniform the product heating.

- Good welding quality: the comparison shows that the temperature of

the work piece welded by solid-state high-frequency is uniform and the

surface is smooth.

- Energy saving: the test shows that this equipment saves more than 30%

of electricity than the electronic tube equipment of the same

specification.

- Water saving: due to its small loss, it does not need too much

cooling water, so the water consumption is more than 50% less than that

of electronic tube equipment of the same specification.

- Light weight: Due to the small size of the main power device

(Mosfet), there are no devices such as filament regulators, matching

coils, and gate circuits.

- Easy to operate: start and use immediately, and stop when you say

stop. There is no need for tube-type preheating or cooling after

shutdown.

- Safe and reliable use: The technology is mature and stable, and the

operation is reliable. Since the working voltage is lower than that of

the electronic tube,it is not easy to cause casualties.

Application

- Cookware pan pot bottom induction brazing machine is mainly used for

cookware composite bottom welding of stainless steel /copper /aluminium

pan, pot, kettle, and can also be used for plane heating of other work

piece. Cookware Pan and pot bottom brazing machine is a mechanical,

hydraulic and electrical integrated equipment, controlled by several

sets microcomputer.

- The main performance indicators take the leading status at home and

aboard.